Here is a well articulated article on why Single-phase, Liquid Immersion Cooling SpLIC is required...

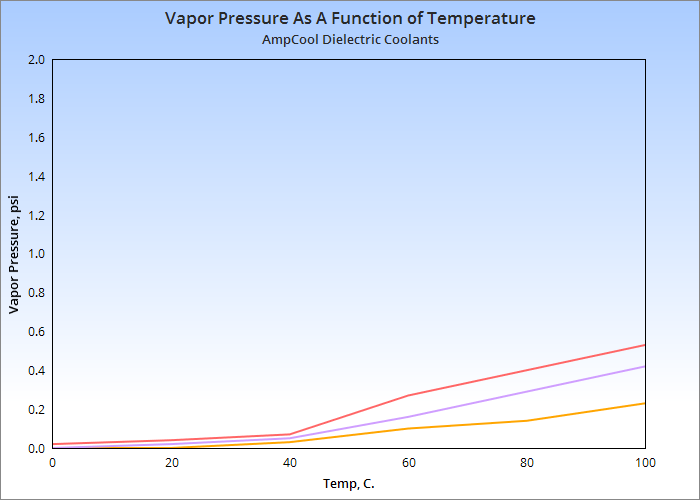

Considering Vapor Pressure...

If you're designing a closed-loop cooling system, be sure to consider the Vapor Pressure of the coolant fluid and how that pressure will change with temperature. As your application temperatures rise, so will the pressure inside your system, perhaps to the point where there's an system overpressure, a catastrophic failure, a blowout or a big huge mess, however you want to call it. Take into account both thermal expansion as well as vapor pressure when designing and choosing fluid enclosures and hose systems.