I received an interesting question last week, about the use of silicone fluid to cool electronics....

Immersion cooling lowers data center fire risks

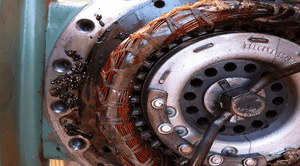

The flammability potential of electrical motors and fans used in Computer Room Air Conditioning (CRAC) units is well known – the National Fire Protection Association (NFPA) identifies fans and motors in CRAC units as a known and significant fire risk in their analysis of “Computer Room and Other Electronic Equipment Areas” (1). The two main failure modes are thought to be electrical short circuit and bearing damage caused from vibration and insufficient lubrication, leading to overheating and fire. In addition to supplying a significant amount of plastic fuel load to burn, fans and fan motors also collect a considerable amount of flammable dust. This dust is electrically conductive, so its buildup can short-circuit the windings of the motor. A greater problem, however, is the potential for short circuit inside the motor, supplying the crucial ignition source required for the combustion process to complete. The NFPA report shows that 16% of data center fires can be traced to air-handling electric motors and fans.

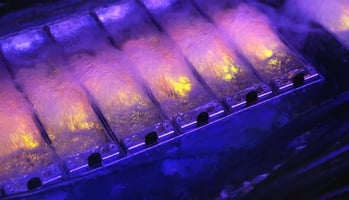

Now contrast this with the safety of liquid immersion cooling. There are no fans, and no fan motors to fail. The dielectric coolant circulates quietly, propelled by a single fluid pump. The failure rate of industrial motors coupled with centrifugal pumps is miniscule. There’s no vibration, no dust, and motor bearings are bathed in lubricant, extending their life. Engineered dielectric coolants, such as ElectroCool Fluids, have dielectric strength that’s thousands of times higher than air, so even if there’s a short circuit in the coolant, there’s no spark or ignition.

At Engineered Fluids, we are working with data center operators and server manufacturers to lower the costs of operating data centers, including equipment failure costs. Immersion cooling can save 50-60% of a data center’s electricity costs, as well as extend the life of computer assets. It’s a win-win for everyone. Unless you sell fire extinguishers.

Citations:

3. S. Karmakar et al., Induction Motor Fault Diagnosis, Power Systems, DOI 10.1007/978-981-10-0624-1_2